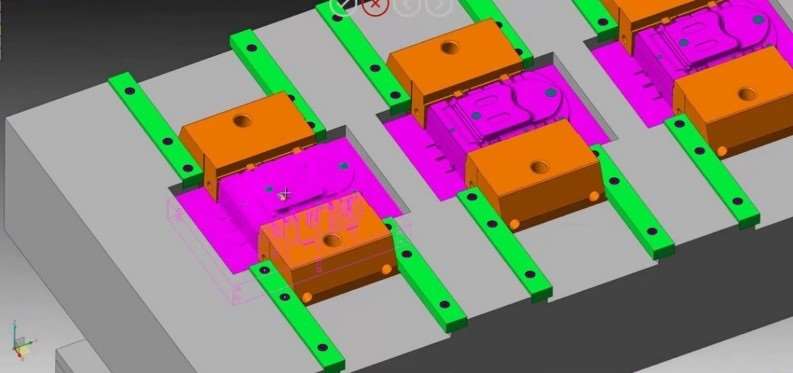

32-cavity tool, with 2 sliders in each cavity, moulding PA6.6 GF30

Problem: Grease from the sliders is running into the cavity, reacts with the plastic additives and forms buildup. The whole tool must be disassembled to remove the deposits mechanically.

Solution: Simple coating of all sliders with a self-lubricating coating CCMold DLC have eliminated grease from the process. Mold is running dry, deposits from plastic can be easily wiped off. This saves 3 work-days of maintenance work per mold per month.

During processing of polymers there is often buildup of degraded plastic material and additives, such as flame retardants, release agents, stabilisators, pigments, antistatic agents. The residues are getting worse and harder when they react with the grease brought to the mould to lubricate moving parts against galling. The deposits are primarily formed in the cavities, but also at ejectors, injection gates and channels.

Buildup leads to contamination of the tool and causes visual changes and defects in the surface, changes in the shape and dimensions of the article and sticking of the parts. The deposits must be removed repeatedly, which is associated with production stops and additional costs.